Peanut Butter Processing Machine Turnkey

Turnkey Peanut Butter Plant Machinery Manufacturer –

Shrijee Nut Company

End-to-End Peanut Butter Processing Solutions with 20+ Years

of Proven Expertise

For over two decades, Shrijee Nut Company has been at the

forefront of peanut butter and Blanch peanut processing technology, delivering

state-of-the-art turnkey peanut butter plants for clients across India and

around the world. With deep technical know-how, in-house manufacturing, and a

proven track record of over 16 successful installations, we don’t just build

machines—we build profitable, scalable peanut butter operations.

From raw peanut intake to packaging, every critical stage of

peanut butter production is covered under our comprehensive plant setup,

excluding the color sorter. We offer much more than machinery—we deliver

process engineering, commissioning, operator training, and expert guidance on

recipe formulation and processing parameters.

Why Shrijee Nut Company?

20+ Years of Experience in Nut Processing

We’ve engineered and evolved with the industry—mastering

roasting, blanching, grinding, blending, and cooling systems tailored for

peanuts.

Complete In-House Manufacturing

Complete Turnkey Supply: From receiving peanuts to roasting

cooling splitting grinding, cooling, and final filling—we supply all machinery

(except color sorter) for seamless operation.

All major machines are built under one roof—ensuring

consistency, customization, reliability, and after-sales service without

third-party dependency.

All our machines are meticulously engineered and designed

in-house, based on proven U.S. technology—not Chinese imports—ensuring superior

quality, hygiene, and long-term reliability.

Global Project Footprint

International Standards: Robust design, food-grade

materials, CE-ready features, and hygienic construction.

Our turnkey peanut butter plants operate successfully in

India and abroad, in markets with stringent international quality norms.

Proven Results – 16+ Turnkey Plants Commissioned

From startup units to export-oriented processing lines,

we’ve helped entrepreneurs and companies achieve success with tailored

solutions.

Over 50 + Roasting, Whole Nut & Split Nut Blanching, and

Sesame Seed Roasting Plants Successfully Commissioned

- Proud

to be the first Indian company to revolutionize the traditional peanut

processing sector—transforming it into a world-class, sophisticated, and

technology-driven industries.

- End-to-End

Process Know-How

- Shrijee

doesn’t stop at equipment delivery—we guide our clients in setting up

batch formulas, heat profiles, viscosity adjustments, and quality control

parameters to produce peanut butter meeting global standards without

needing outside consultants.

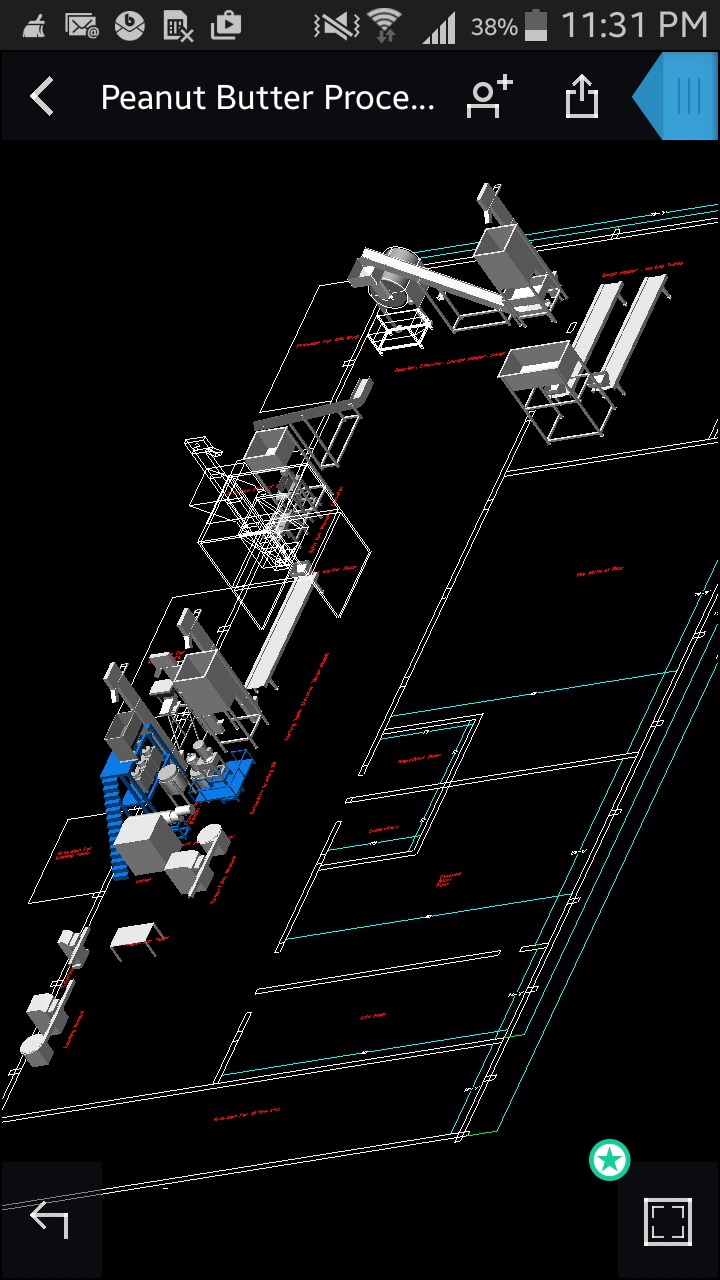

Peanut Butter Processing Flow – Fully Engineered by

Shrijee Nut

1. Raw Peanut Feeding via Z-Elevator

Gentle transfer to reduce kernel breakage

2. Surge Hopper with (2 Ton) below charge hopper with

Load Cell

Accurate batch control for feeding roaster

3. Ray-O-Matic Infrared Ray rotary Roaster

Precision-controlled roasting using infra Ray technology

4. Modular Cooling Belt with Suction Blower

Rapid cooling to preserve color and flavor

5. Z-Elevator to Split Nut Surge Hopper

Smooth flow transition before blanching

6. Split Nut Blancher (Rubber Belt Type)

Removes skin and hearts with minimal product loss

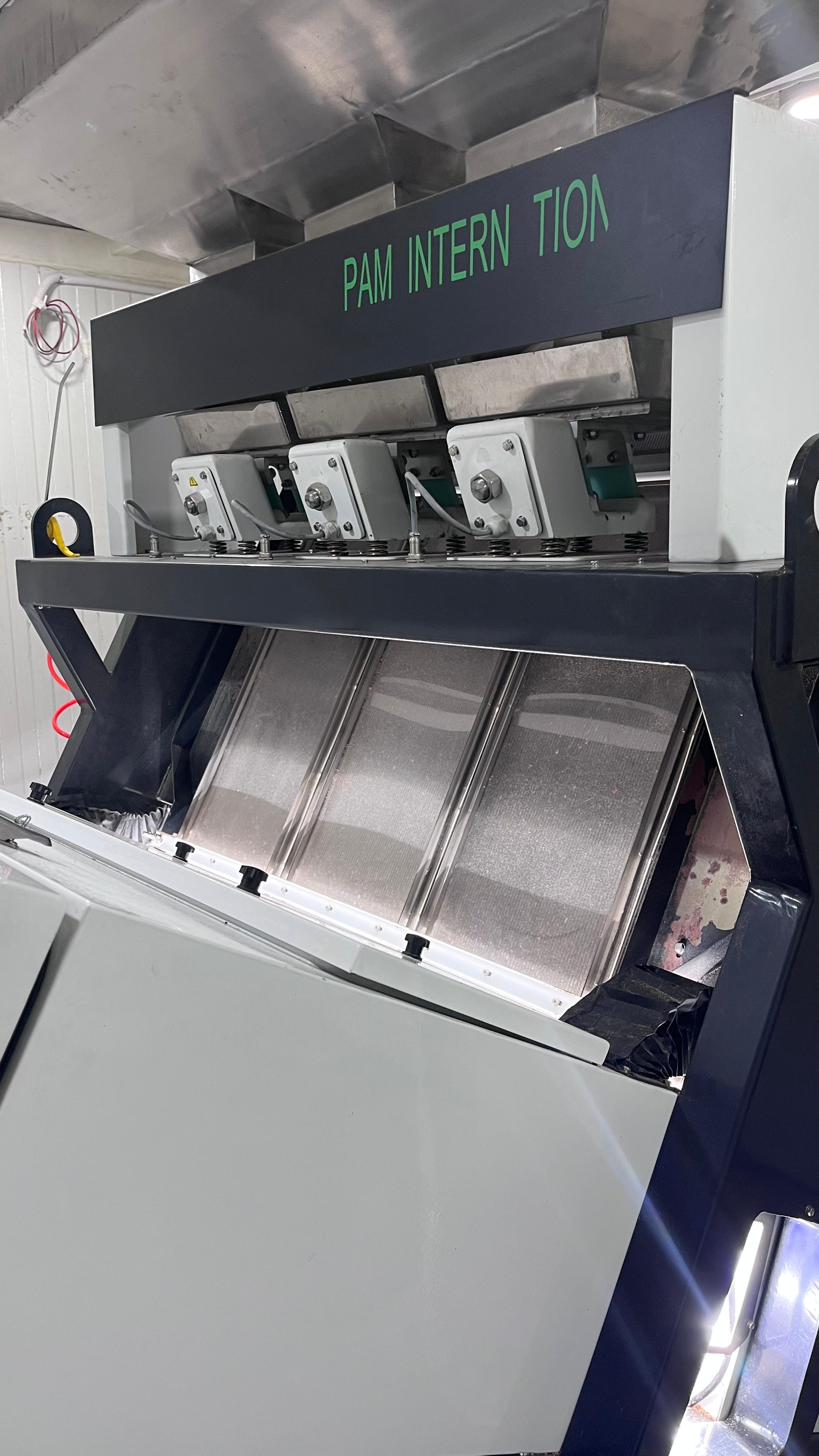

7. Optional Color Sorter (Customer Supplied)

We integrate system space & feed provision

8. Manual Sorting Table with Suction Chute

Final inspection of splits to remove damaged seeds

9. Batch Surge Hopper below load cell Batch hopper-to

Ribbon Blender

Controlled batch feeding for ingredient mixing

10. Ribbon Blender

Uniform blending of sugar, salt, stabilizers, or other

additives

11. Primary Grinding Unit

Produces coarse paste from blended material

12. Agitator Holding Tank + Gear Pump

Prevents settling and ensures smooth material flow

13. Micro Cut Grinder (Silky Finish)

High-speed grinding for fine, uniform, smooth texture

14.Agitator Holding Tank + Gear Pump

Prevents settling and ensures smooth material flow to SSHE

15. SSHE (Scraped Surface Heat Exchanger)

Cools peanut butter to 30°C filling temperature

16. Automated Filling, Lidding, and Labeling Line

Final step – packaging for domestic or export sales

Optional: Color Sorter and Chiller can be integrated as per

client preference.

Beyond Machinery: Process Standardization for Global Peanut

Butter Markets

Shrijee Nut ensures that every plant we install is

process-ready. Our commissioning team trains your staff on:

• Roasting Time & Temperature Profiles

• Blanching Adjustment & Split Recovery

• Ribbon Blender Batch Timing & Mixing Ratio

• Primary vs Micro Grinding Settings

• Heat Load & Cooling Rate Management in SSHE

• Peanut Butter Consistency, Texture, and Viscosity Control

• Stabilizer & Flavor Integration

With this hands-on support, you gain the capability to

produce globally acceptable peanut butter—including smooth, crunchy, chocolate,

natural, or customized recipes—without external consultants or recurring

technical dependence

Serving Global Ambitions from India

Shrijee Nut’s turnkey systems serve clients across:

• India

• Middle East

• Africa

• Southeast Asia

We understand regional preferences, regulatory norms, and

food safety compliance—and tailor your plant accordingly.

Let’s Build Your Peanut Butter Vision

Shrijee Nut Company invites global buyers, food processors,

and plant consultants to explore custom turnkey peanut butter processing

plants. Whether you’re expanding capacity, entering new markets, or upgrading

technology—we’re your dependable partner from concept to commissioning.

Whether you’re upgrading an existing plant or starting from

scratch, Shrijee Nut Company provides you with the technology, training, and

trust you need to succeed.

Contact us today to start your peanut butter journey!

Custom layouts, automation options, and export documentation

support available.