Peanut Radiant Ray Rotary Roaster

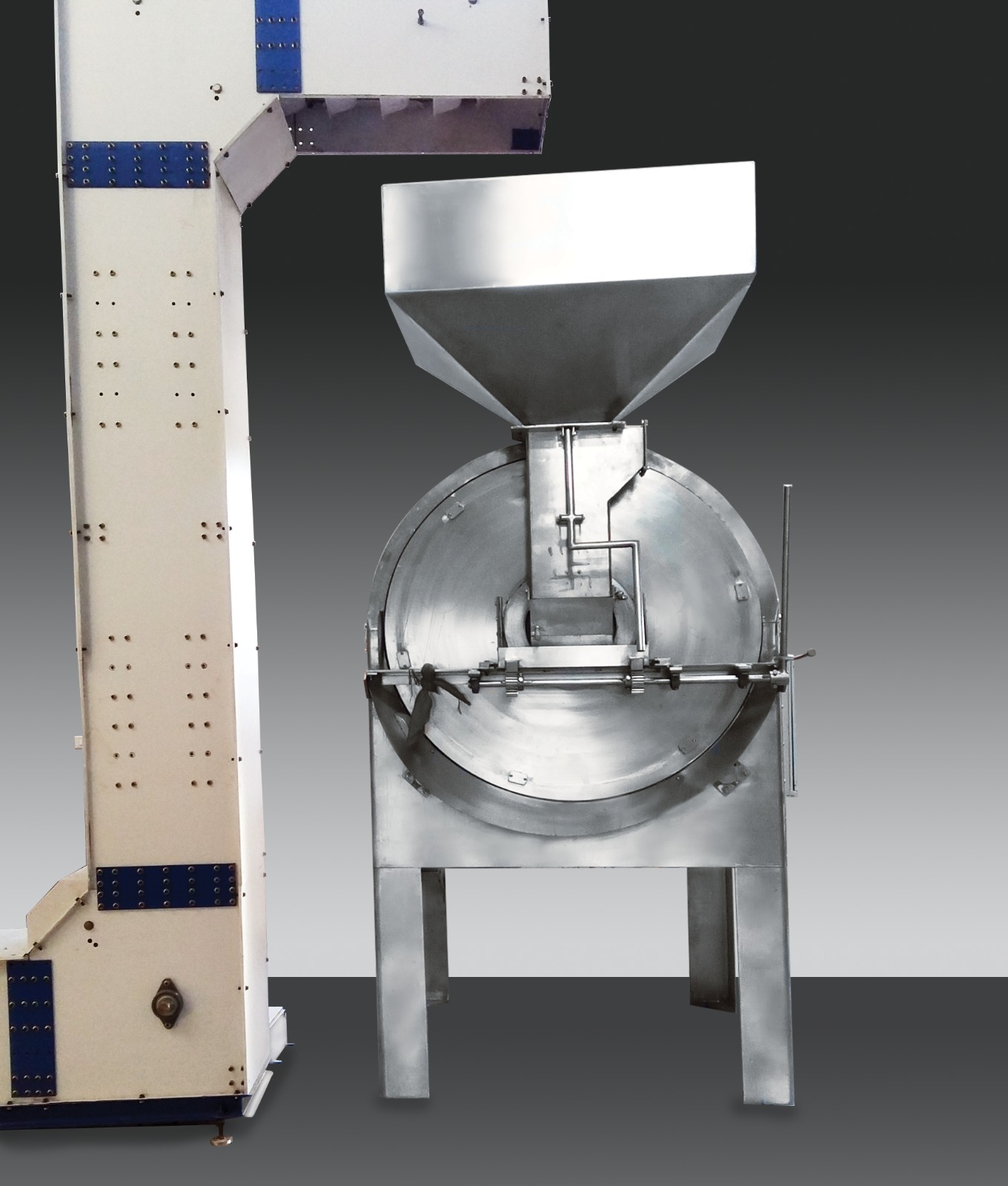

Radiant Ray( Ray-O-Matic ) Infra Ray Rotary Batch Roaster ( PEANUT ROASTER )

World-Class Roasting Technology by Shrijee Nut Co.

Unlock the full FLAVOUR potential of your nuts and seeds with Shrijee’s Ray -O Matic Rotary Batch Roaster — the industry’s most advanced solution for uniform, efficient, Gentle and fuel-saving roasting. Built with patented Direct Infrared like Heating Technology, this roaster delivers consistent results across a wide range of products,— from peanuts, cashews, pistachios, and almonds to sesame, sunflower seed, coriander, fennel, cumin and other soft or hard seeds and grains.

it is an ideal choice for processors seeking high-quality output with lower operational costs.

Why Choose Radiant Ray Roasting?

· Infrared radian ray roasting transfers radiant heat directly to the product, allowing faster, even roasting while preserving essential oils, flavor compounds, and natural color. It reduces oxidation and ensures extended shelf life — all without pre-heating chamber , saving time and energy.

· Accurate Temperature Control

· Fine-tuned temperature monitoring prevents under or over-roasting, enabling ideal texture and taste every time.

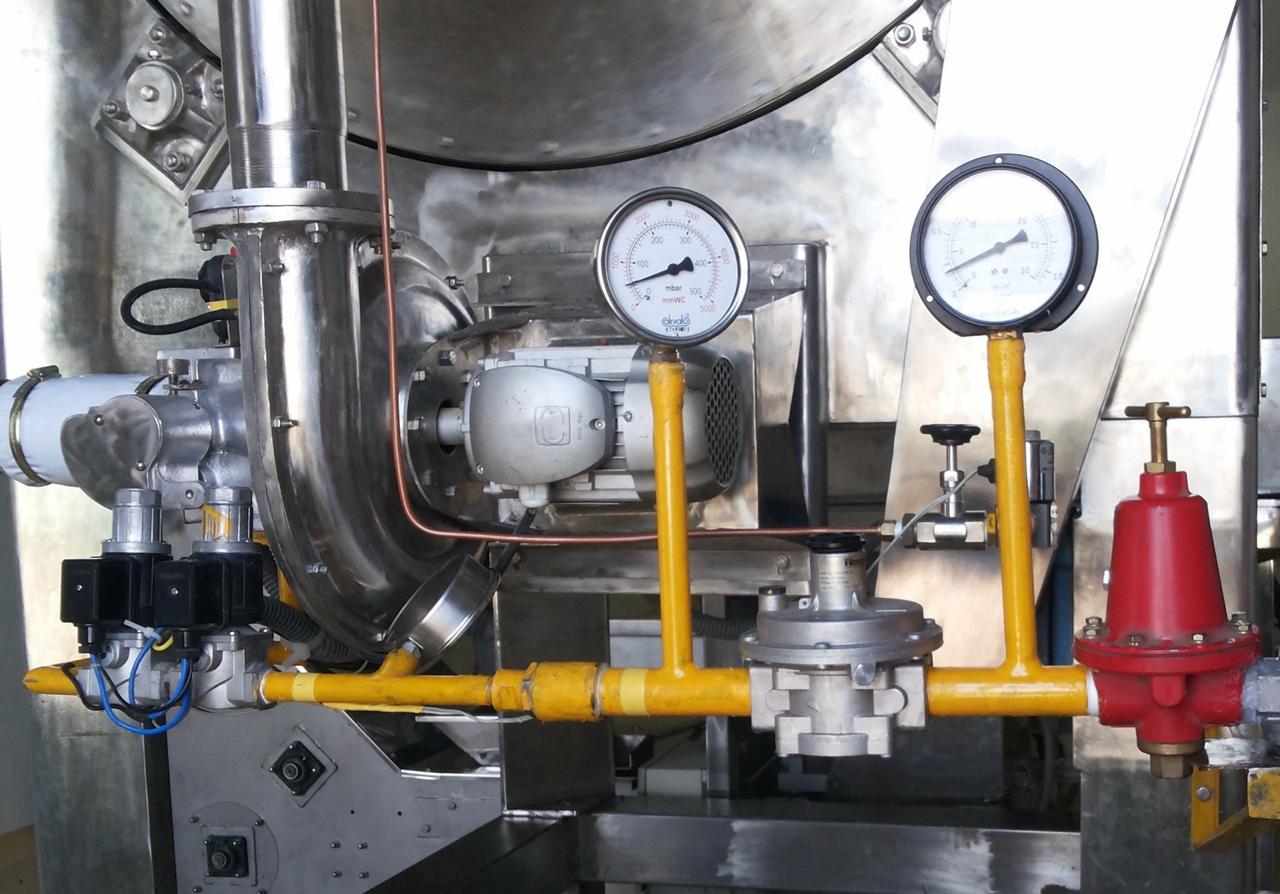

· Fuel-Efficient Combustion System

· Direct heating requires no warm-up time, reducing energy usage.

· A combination of premix fuel valve and blower ensures clean, efficient burning distribution and low carbon emissions — minimizing energy consumption.

· Flame-Out Safety System

· Automatic fuel cut-off in case of flame failure guarantees safe and uninterrupted operation.

· Self-Cleaning Mechanism

· Built-in cleaning system reduces downtime and maintenance needs — improving overall operational efficiency.

· Intelligent Batch Roasting System – Seamless & Continuous Closed-Loop Batch Control Operation

· A surge hopper positioned above the roaster’s feeding chute allows for pre-loading of the next batch during the roasting of the current one. Once the roasting cycle is complete, the outlet door opens, discharging the roasted batch into the hopper of the cooling belt system within 60 second.

The product then moves across the cooling belt for cooling down. Immediately after the outlet door closes, the feed gate of the surge hopper opens, releasing the next batch into the roaster. Once the surge hopper is emptied, the dumper is closed, and the system is ready to accept a fresh batch.

This intelligent sequence eliminates the need to switch off the power or flame, enabling the batch roaster to operate in a continuous loop—delivering the efficiency of a continuous roaster with the precision of batch processing.

Thanks to automated feedback control, the system maintains consistent roasting quality across all batches, reduces human error, and maximizes throughput..

No Dark Patches or Uneven Roast

Even distribution of Radiant heat ensures even colour penetration without scorched or raw areas.

Versatile Roasting Applications :

•Suitable for a wide range of products:

• Peanuts (shelled/unshelled)

• Almonds, diced cashews, pistachios

• Sesame, pumpkin, sunflower seeds

• Coriander, fennel, cumin and other grains/spices

• Handles product sizes from 2mm to 20mm and moisture content up to 14%.

Manual or Fully Automated Operation

Choose between simple manual controls or full automation to match your production requirements.

Integrated Cooler Option : Belted cooler available for efficient post-roast handling.

MODEL | CAPACITY |

RSTR150 | 450 kg / hr |

RSTR300 | 900 kg / hr |

Batch Cycle Time: 20–25 minutes (up to 3 batches/hour)

Heavy-duty, MS WITH CONTACT PARTS SS OR SS CONSTRUCTION prewired & program-tested for plug-and-play operation.

Optional Integration: Belted continuous cooler available for seamless post-roast cooling

Over 20 years of experience in nut processing technology with a strong track record of performance and reliability, more than 60 Shrijee Roasters are currently in operation across India and international markets.

Industry-leading radiant heating design

Engineered for fuel efficiency and low emissions

Scalable capacities for artisanal and industrial processors

Proudly made with Indian craftsmanship and global standards

Peanut Butter and Peanut Paste Manufacturing

Blanched Peanut Processing

Sesame Seed Roasting

Spice Roasting

• Superior flavor development

• Consistent, uniform roasting results

• Reduced operational costs

• Reliability in both small and large-scale production

Get in touch with our team to:

• Schedule a demo

• Get a custom quotation

• Learn how Shrijee’s roasting technology can upgrade your production line.