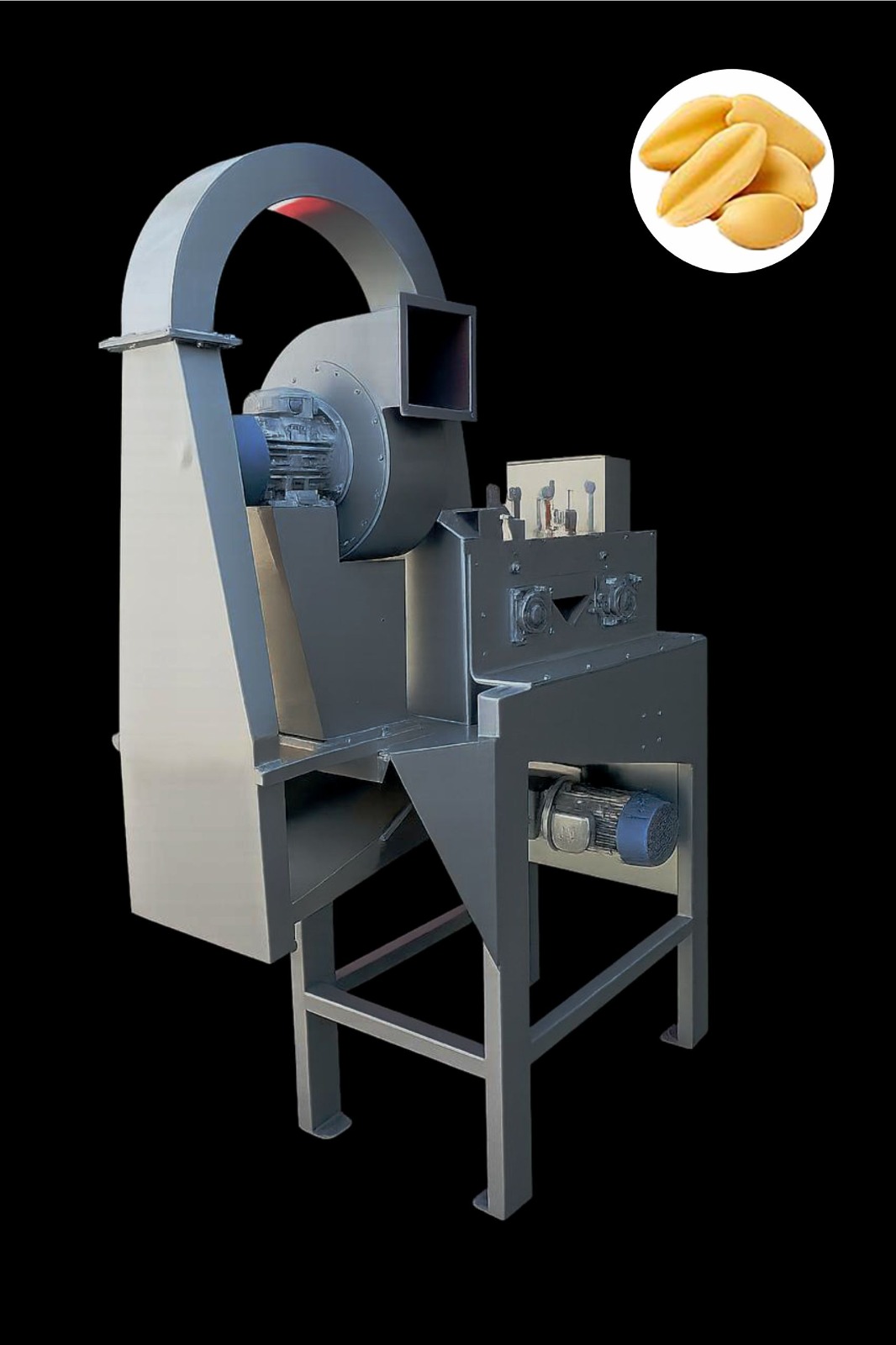

Peanut Split Blancher

Split Nut Blancher – Precision Blanching, Maximum Yield

Engineered for the clean removal of peanut skins and hearts,

our Split Nut Blancher delivers high-speed, gentle processing with minimal

shrinkage and outstanding efficiency. Ideal for roasted peanut lines producing

peanut butter, snacks, and confections, this machine combines rubber-based

blanching, dual aspiration, and advanced screening for optimal results.

With a processing capacity of two Model 500 kgs/hr and

1000kgs/hr , the system minimizes product shrinkage and waste while enhancing

overall product quality. Its modular, compact design allows easy integration

into existing production lines.

Having rubbing technology in our split nut blancher, this

machine can also be used for removing skin of the roasted chickpeas without

damaging and broken. Product surface remain shiny and having very less broken

with the help of this machine.

Core Features & Advantages

Dual-Aspiration System – Ensures 100% removal of loose peanut skins for a clean, finished product.

·

Rubber Blanching Elements – Gently remove skins

without damaging kernels, reducing shrinkage.

·

Adjustable Blanching Plate – Accommodates

varying peanut sizes for uniform blanching results.

·

Vibro Sieve with Dual Screens – Effectively

separates unblanched nuts, split hearts, and clean halves.

·

Adjustable Feed Hopper – Enables smooth,

controlled feeding into the blanching chamber.

·

Energy Efficient – Designed for low power

consumption with high output.

·

Easy to Operate & Maintain – User-friendly

interface and quick-clean features minimize downtime.

·

Durable Construction – Built with

industrial-grade materials for long-term, heavy-duty performance.

Our blanching system follows a three-stage process to

deliver clean, split peanuts ready for further processing or packaging:

1. Splitting & Skin Removal

Peanuts are gently split, and their skins are loosened and

detached using precision rubber elements.

2. Heart Separation

Internal hearts are automatically separated from peanut

halves for quality assurance.

3. Screening & Final Aspiration

Vibro sieves and dual aspiration units ensure complete

removal of residual skins and proper grading.

• Trusted by leading peanut processors in India and abroad

• Backed by Shrijee’s experience in turnkey peanut butter

plants

• Designed to meet global quality and food safety standards

• Delivered with expert installation, training &

after-sales support

Contact us today to learn how the Shrijee Peanut Blanching

Machine can streamline your production and improve product quality.

FAQs:

Ans: It can process 500–1000 kg of roasted

peanuts per hour, ensuring high productivity.

Q2: What additional features enhance its performance?

Ans: Rubber blanching elements reduce shrinkage,

while the optional mounting and cyclone improve efficiency and skin collection.

Q3: How does the machine ensure complete skin removal?

Ans: The dual-aspiration system effectively

removes 100% of loosened skins, delivering smooth, clean nuts

Ans: Its adjustable blanching plate ensures

effective blanching for all sizes of nuts, whether graded or ungraded.

Ans: Yes, it is easy to operate and clean,

featuring a trouble-free feed hopper and a vibro sieve for leftover nut

removal.